Quality Control

Noor Neda’s Quality Control Dept., since its inception with complete control over the production cycle, has put forward two important and general principles of “quality” and “customer-oriented” and believes in achieving these consistent goals. Supervises and controls the process of supplying materials and equipment, product manufacturing processes and sales and customer satisfaction (meeting customer needs and demands). This unit strives to have its production process continuously monitored, utilizing its experienced quality control experts and advanced testing equipment, to ensure the accuracy and quality of its products. In this regards, the products shall be evaluated and tested in 3 stages: input control, control during the process, control of the final product.

Input Control

All items are sampled after entering to the factory and tested in accordance with the relevant standards and if confirmed, are sent to production lines for using. Controlling process of entering parts is performed by Shetabkar Laboratory, which is equipped with precise and advanced test and control devices and are continually calibrated by accredited laboratories.

Control in Process

In this step, parts are controlled and sampled randomly regarding the changes and kind of process which are carried on them, from the aspects of appearance, dimensions and performance tests.

Final Product Control

In this step, it is sampled from the final product and all controlling and inspections are done on them in accordance with relevant standards of all aspects like observing control (packaging), dimensional control (standard and defined parameters) and function control (practical & laboratory tests) and after getting confidence, products are delivered to customers.

Objectives of Quality Control Department

To enhance its product portfolio Noor Neda Company pursues the following goals as its constant objectives:

- Maintain organizational standards

- Correction of production process deviations

- Evaluate the performance of each production halls based on the type of product

- Increasing quality

- Improve the business process

- Increase Productivity

Obviously, achieving any of these goals would not be possible without proper equipment. Therefore, by using precision laboratory equipment, Noor Neda Quality Control Laboratory strives to provide the right services to its customers.

Testing and control devices

- Luxury Meter: A luxury meter is a “brightness” measuring device with a lux unit. The device senses the “light intensity” on the surface of the sensor and, according to the conversion coefficients assigned to the digital device, indicates the intensity of the local illumination where the sensor is located.

Measuring range from 1000 to 25000 lux

- Sound Testing: Sound measurement devices can be used to measure ambient noise. The product is designed for this purpose and can measure and display sound in about 125 microseconds. It has a high performance speed and has a measuring range of 40-130 dB.

- Color Stability Test: It measures the refraction rate and color persistence of sunlight, the ozone layer and environmental conditions by ultraviolet radiation.

- Heat Testing: Infrared Testing is another non-destructive method of component testing. The test uses infrared waves emitted from hot objects to detect discontinuities in the fragments. This detection is performed using infrared cameras.

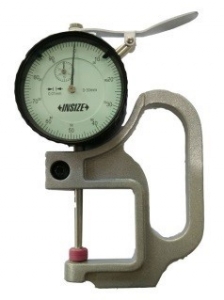

- Thickness Gauge: This device is used to control the thickness of injection bubbles by the company.

- Wind and Rain Test: This allows the water permeability of the lights to be monitored and tested at different speeds. The test is carried out at a speed of up to 140 km/h and a wind speed of 7 cubic meters per second and a water injection of 330 liter/min at a pressure of 5.5 bar.